Cold Forging is a forming process of material close to room temperature. In Cold Forging, the material is formed by using pressure and high speed into the dies (mold). This workmanship can add a level of hardness to produce good tensile strength.

INTEGRETED PRODUCTION SYSTEM

COLD FORGING

By efficiently employing five parts formers in three different types, we are developing near net shape manufacturing of cold-forged materials. We are seeking not only to cut cost, but also to manufacture in a more Early-friendly manner. Putting know-how gained from cold-forging technology to work, we are developing in-house manufacturing of metal dies.. [ view more ]

MACHINING

Machining is a term used to describe a disposal of material from a workpiece, covering several processes usually divided into the following categories.. [ view more ]

HEAT TREATMENT

Heat treatment is a process of changing a microstructure in metal materials and alloys, such as steel and aluminum so that it is useful as a power component. For example additions to the surface hardness, temperature resistance sildenafil 100 mg durée de l’effet, elasticity and durability of a material.. [ view more ]

ASSEMBLY

The assembly process is combine several child parts or supporting components into a product that can function in accordance with the purpose of its manufacture.. [ view more ]

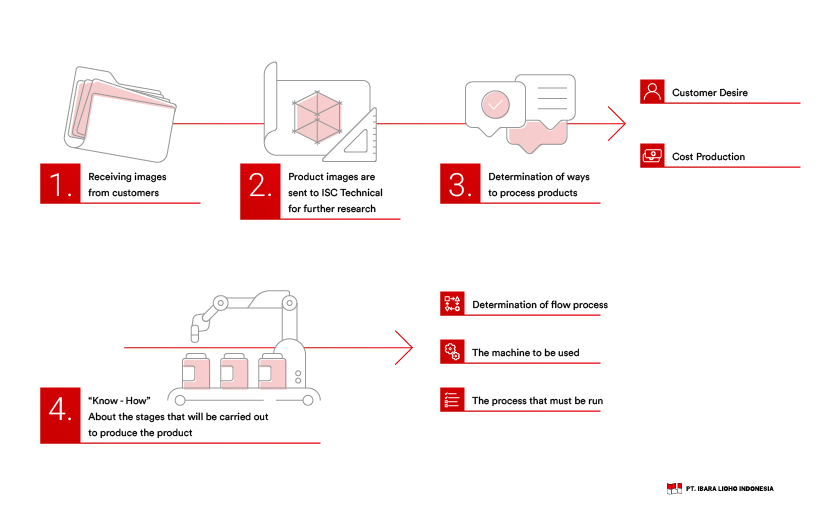

Realization of assured high quality from

integrated production system

Proposal of products based on customer

need and wants